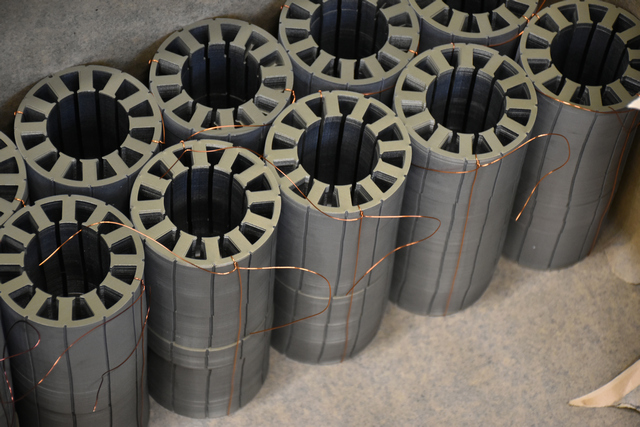

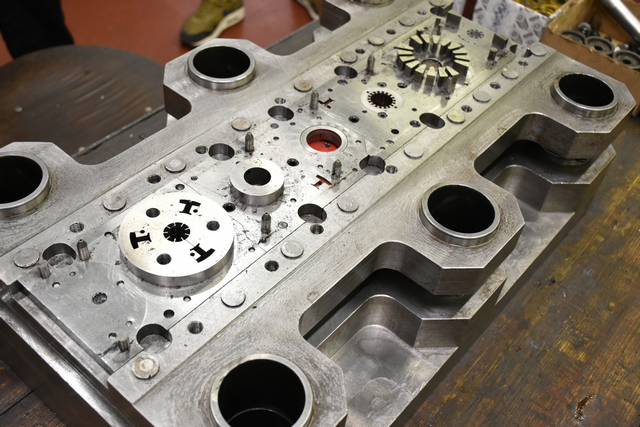

PRESS SHOP

The main task of the press shop department is stator and rotor sheet metals puching mainly determined for servomotor assembly. We are equipped with a modern SWISS made high-speed press BRUDERER with the press force 160t., that can process material up to 3 mm thickness and 300 mm width. Large symmetrical components, small series and prototypes are processed on a notching press using alternative methods. Our tool equipment also includes eccentric press with the press force 63t. Electrotechnical sheet metals are punched on tools of our own construction.